1. Precautions for transporting frozen fish

1. Keep the temperature on hold

Frozen fish must be kept at-18°C or lower to prevent thawing and deterioration. Maintaining a stable low temperature throughout transport is crucial.

2. Packaging integrity

Proper packaging is key to protecting fish from temperature fluctuations, physical damage and contamination. The package shall be durable, leaky, and insulated.

3. Humidity control

Minimize the humidity in the package to prevent ice crystals and frozen cautery, which reduces the quality of the fish.

4. Transportation time

Plan transportation routes and duration to ensure that fish are always frozen before reaching their destination. Use an expedited transport method, if necessary.

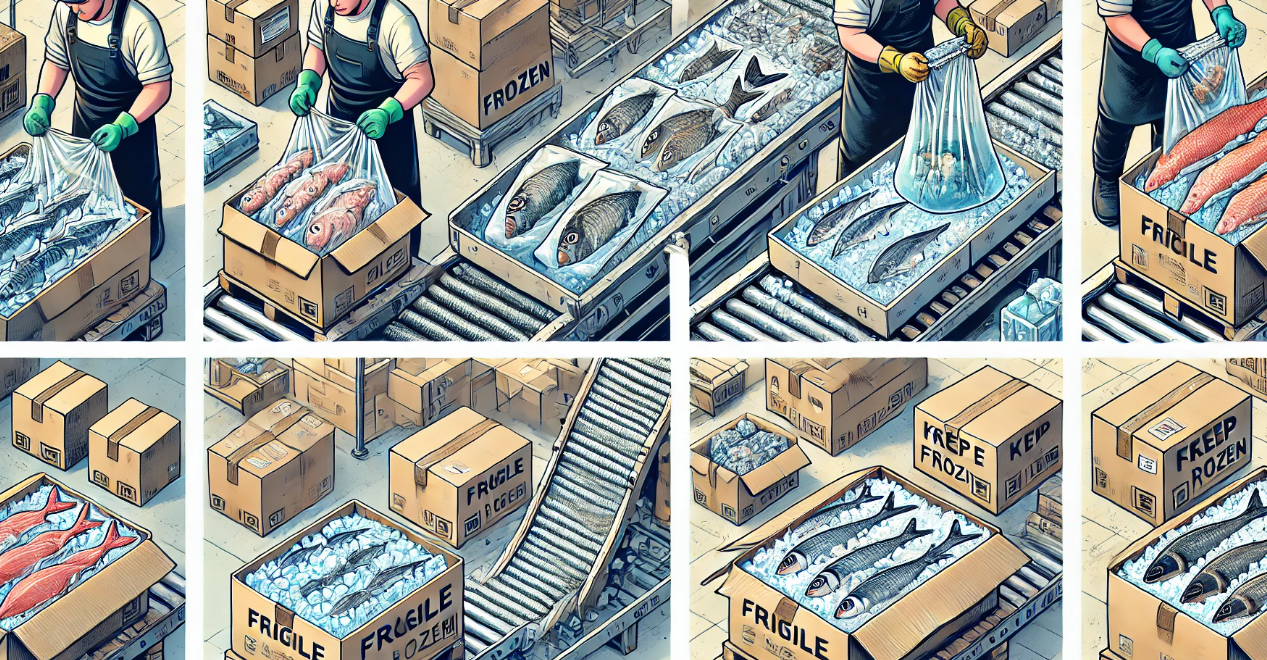

2. Packaging steps

1. Prepare the materials

-Vacuum sealing pockets or moisture-proof packaging

-High-performance thermal insulation container (EPS, EPP, or VIP)

-Condensant (gel ice packs, dry ice, or phase change material)

-Hygroscopic pads and bubble pads

2. Pre-cooled fish

Make sure the fish is completely frozen before packaging. This helps to maintain a stable internal temperature during transport.

3. Vacuum seal or pack the fish

Fish fish using vacuum sealing pockets or moisture-proof packaging, which prevents air exposure and reduces the risk of freezing cautery.

4. Arrange the refrigerant

Place the pre-cooled fish in an insulated container. Spread the refrigerant (such as gel ice packs, dry ice, or phase change materials) evenly in the surroundings to ensure uniform temperature distribution.

5. Fix and seal the containers

Use a bubble cushion or foam to prevent movement during transport. Close tight tightly to prevent air exchange and temperature fluctuations.

6. Mark the packaging

Clearly marked packaging, labeled “perishable items” and “keep frozen”. Include handling instructions for transport personnel reference.

3. Temperature control method

1. Choose the appropriate thermal insulation material

Select the appropriate insulation containers according to the transportation time and external conditions:

-EPS container: lightweight and cost effective for short to medium duration transportation.

-EPP container: durable and reusable for long time transportation.

-VIP container: high performance thermal insulation, suitable for long time transportation and highly sensitive products.

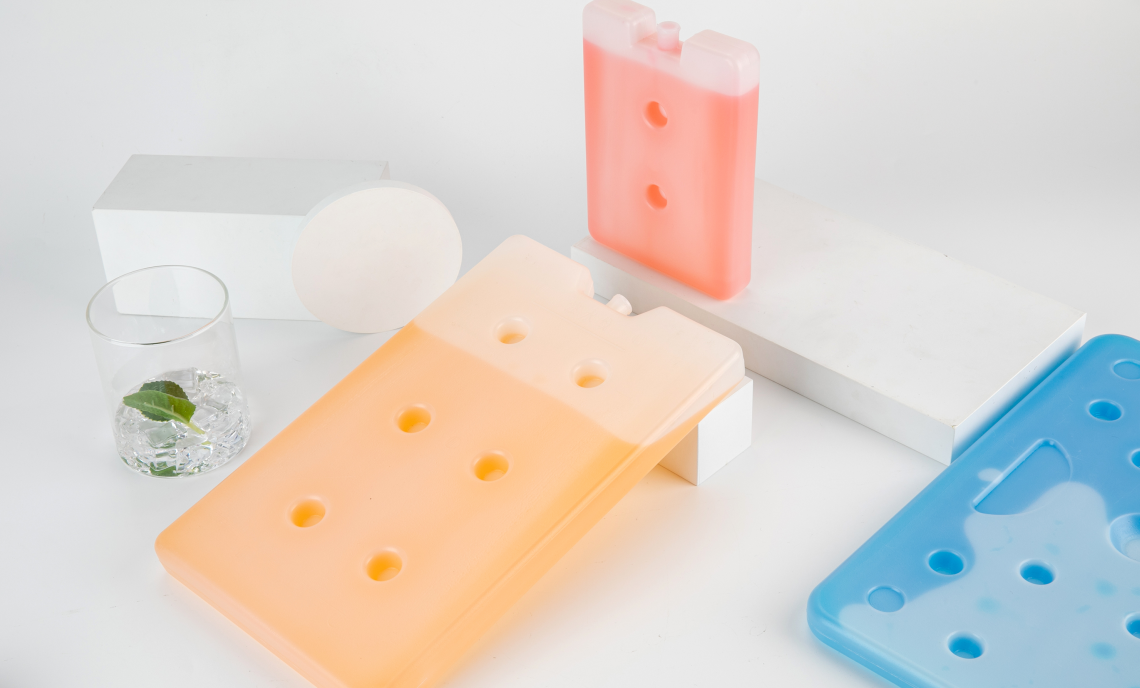

2. Use the appropriate refrigerant medium

Choose a refrigerant suitable for the transportation needs:

-Gel ice pack: Suitable for short to medium length, non-toxic and reusable.

-Dry ice: Suitable for long time transportation, maintaining extremely low temperatures. Due to its extremely low temperature and sublimation properties require careful treatment.

-Phase change material (PCM): Provide accurate temperature control for multiple transportation times and can be reused.

3. Temperature monitoring

Use the temperature monitoring equipment to track the temperature throughout the transportation process. These devices can alert temperature deviations, allowing you to take immediate corrective action.

4. Huizhou’s professional solutions

Maintaining the temperature and freshness of food is critical when transporting frozen fish. Huizhou Industrial Cold Chain Technology Co., Ltd. provides a series of efficient cold chain transportation products, the following is our professional proposal.

1. Huizhou products and applicable scenarios

1.1 Inwater ice pack

-Main application temperature: 0℃

-Applicable scenario: For products that need to be maintained around 0℃, but not suitable for frozen fish transportation.

1.2 Saline water ice pack

-Main application temperature range: -30℃ to 0℃

-Applicable scenarios: Suitable for frozen fish that require lower temperatures but not extreme low temperatures.

1.3 Gel ice pack

-Main application temperature range: 0℃ to 15℃

-Applicable scenario: suitable for slightly cold products, but not suitable for frozen fish transportation.

1.4 Organic phase change materials

-Main application temperature range: -20℃ to 20℃

-Applicable scenario: suitable for accurate temperature control transportation in different temperature ranges, but not suitable for frozen fish transportation.

1.5 Ice box ice board

-Main application temperature range: -30℃ to 0℃

-Applicable scenario: suitable for short-haul transportation and need to keep frozen fish cold.

2.insulation can

2.1 The VIP incubator

-Features: Use vacuum insulation plate technology to provide the best insulation effect.

-Applicable scenario: Suitable for extreme low temperature requirements and the transportation of high-value frozen fish.

2.2 EPS incubator

-Features: Polystyrene materials, low cost, suitable for general thermal insulation needs and short-distance transportation.

-Applicable scenario: Suitable for frozen fish transport requiring moderate insulation effect.

2.3 EPP incubator

-Features: high density foam material, provide good insulation performance and durability.

-Applicable scenario: Suitable for frozen fish transportation requiring prolonged insulation.

2.4 PU incubator

-Features: polyurethane material, excellent thermal insulation effect, suitable for long-distance transportation and high requirements of thermal insulation environment.

-Applicable scenario: suitable for long distance and high value frozen fish transportation.

3.thermal bag

3.1 Oxford cloth insulation bag

-Features: light and durable, suitable for short-distance transportation.

-Applicable scenario: suitable for small batches of frozen fish, but not recommended for long-distance transportation due to limited insulation effect.

3.2 Non-woven thermal insulation bag

-Features: environmentally friendly materials, good air permeability.

-Application scenario: suitable for short distance transportation for general insulation requirements, but not recommended for frozen fish transportation due to limited insulation effect.

3.3 Aluminum foil insulation bag

-Features: reflected heat, good thermal insulation effect.

-Applicable scenario: suitable for medium and short distance transportation and need insulation and moisturizing, but should be used with other insulation materials.

4.According to the recommended protocol for the frozen fish species

4.1 Long-distance frozen fish transportation

-Recommended solution: Use dry ice, combined with a VIP incubator, to ensure that the temperature remains at-78.5℃ to maintain the freezing state and freshness of the fish.

4.2 Short-haul frozen fish transportation

-Recommended solution: Use saline ice packs or ice box ice sheets, paired with a PU incubator or EPS incubator, to ensure that the temperature is maintained between-30℃ and 0℃ to keep the fish frozen.

4.3 Frozen fish transportation midway

-Recommended solution: Use saline ice packs or ice box ice plates with an EPP incubator to ensure that the temperature is maintained between-30℃ and 0℃ to maintain the freezing state and freshness of the fish.

By using Huizhou’s refrigerant and insulation products, you can ensure that frozen fish maintain the best temperature and quality during transportation. We are committed to providing our customers with the most professional and efficient cold chain transportation solutions to meet the transportation needs of different types of frozen fish.

5.Temperature monitoring service

If you want to obtain the temperature information of your product during transportation in real time, Huizhou will provide you with a professional temperature monitoring service, but this will bring the corresponding cost.

6. Huizhou’s commitment to sustainable development

1. Environmental-friendly materials

Our company is committed to sustainability and use environmentally friendly materials in packaging solutions:

-Recyclable insulation containers: Our EPS and EPP containers are made of recyclable materials to reduce environmental impact.

-Biodegradable refrigerant: We provide biodegradable gel ice packs and phase change materials, safe and environmentally friendly, to reduce waste.

2. Reusable solutions

We promote the use of reusable packaging solutions to reduce waste and reduce costs:

-Reusable insulation containers: Our EPP and VIP containers are designed for multiple use, providing long-term cost savings and environmental benefits.

-Reusable refrigerant: Our gel ice packs and phase change materials can be used multiple times, reducing the need for disposable materials.

3. Sustainable practice

We adhere to sustainable practices in our operations:

-Energy efficiency: We implement energy efficiency practices during manufacturing processes to reduce the carbon footprint.

-Reduce waste: We strive to minimize waste through efficient production processes and recycling programs.

-Green Initiative: We are actively involved in green initiatives and support environmental protection efforts.

7. Packaging scheme for you to choose

Post time: Jul-12-2024