1. Notes for shipping a cheesecake

Keep shipping cheesecake low to avoid temperature fluctuations. Use an efficient incubator and ice packs, and make sure the cake is under 4°C. The cake should be wrapped with a moisture-proof film to prevent the moisture influence. During transportation, avoid violent bumps and make sure the cake is intact.

2. How do I wrap it?

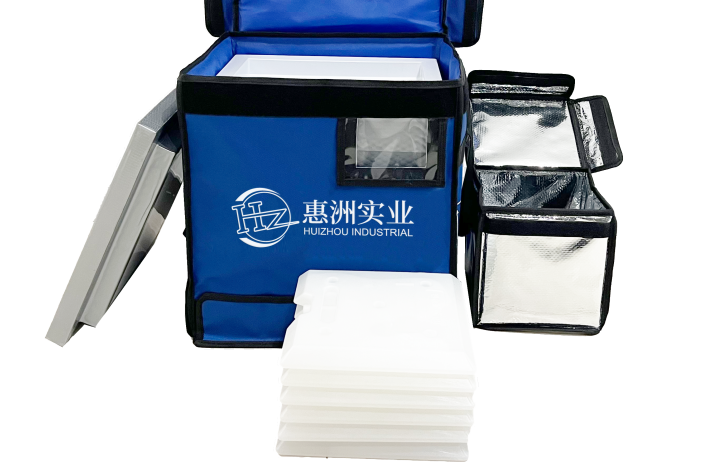

First, pre-cool the cheesecake to the appropriate temperature, and then wrap it in a moisture-proof film or plastic wrap to ensure that the cake is not affected by moisture. Choose an efficient incubator, such as EPS, EPP or VIP incubator, and place gel ice packs or technology ice evenly at the bottom and around the box to ensure the temperature stability. Place the wrapped cheesecake in an incubator and fill the gaps with foam or bubble pads to prevent the cake from moving during transport. Finally, make sure that the incubator is well sealed and labeled as “fragile items” and “refrigerated transportation” on the outside to remind logistics personnel to handle it carefully. This packaging method effectively keeps the cheesecake cold and intact.

3. How can I control the temperature?

1. Choose the appropriate thermal insulation material

-Using EPS, EP, or VIP incubator, these materials have good insulation performance and can effectively prevent the influence of external temperature on the temperature in the incubator.

-Select the appropriate incubator type based on transport distance and time to ensure low temperature for a long time.

2. Use the appropriate refrigerant medium

-Place sufficient amounts of gel ice packs or technology ice evenly at the bottom and around the incubator to effectively maintain low temperatures.

-The refrigerant should be frozen to the appropriate temperature in advance, and the quantity should be adjusted according to the transportation time and ambient temperature to ensure the whole temperature stability.

3. Real-time temperature monitoring

-Place the temperature monitoring equipment in the incubator to monitor the temperature change in the incubator in real time.

-If the temperature is abnormal, timely measures can be taken, such as adjusting the position of ice packs or increasing the number of ice packs, to ensure that the temperature is always below 4°C, to ensure the safe and fresh cheesecake.

4. What can Huizhou do for you?

1. Huizhou products and applicable scenarios

-Water injection ice bag:

-Main application temperature: 0℃

-Applicable scenario: Suitable for cooked food that needs to be kept around 0℃, such as some food that needs to be kept low but not frozen.

-Salt water ice bag:

-Main application temperature range: -30℃ to 0℃

-Applicable scenarios: For cooked foods that require lower temperatures but not extreme low temperatures, such as some refrigerated meat and seafood.

-Gel Ice Bag:

-Main application temperature range: 0℃ to 15℃

-Applicable scenarios: For cooked food at slightly low temperatures, such as cooked salad and some fresh cooked food that need to be kept low.

-Organic phase change materials:

-Main application temperature range: -20℃ to 20℃

-Applicable scenario: suitable for accurate temperature control transportation in different temperature ranges, such as high-end cooked food required to maintain room temperature or refrigerated.

-Ice box ice board:

-Main application temperature range: -30℃ to 0℃

-Applicable scenario: cooked food for short transportation and at a certain refrigerated temperature.

-VIP insulation can:

-Features: Use vacuum insulation plate technology to provide the best insulation effect.

-Applicable scenario: For the transportation of extreme temperature requirements and high-value cooked food.

-EPS insulation can:

-Features: Polystyrene materials, low cost, suitable for general thermal insulation needs and short-distance transportation.

-Applicable scenario: suitable for the transportation of cooked food requiring moderate insulation effect.

-EPP insulation can:

-Features: high density foam material, provide good insulation performance and durability.

-Applicable scenario: suitable for transportation requirements requiring long insulation.

-PU insulation can:

-Features: polyurethane material, excellent thermal insulation effect, suitable for long-distance transportation and high requirements of thermal insulation environment.

-Applicable scenario: suitable for long distance and high value cooked food transportation.

-Oxford cloth insulation bag:

-Features: light and durable, suitable for short-distance transportation.

-Applicable scenario: suitable for the transportation of small batch of cooked food, easy to carry.

-Non-woven fabric insulation bag:

-Features: environmentally friendly materials, good air permeability.

-Applicable scenario: suitable for short distance transportation for general insulation requirements.

-Aluminum foil insulation bag:

-Features: reflected heat, good thermal insulation effect.

-Applicable scenario: suitable for short and medium distance transportation and cooked food requiring heat insulation and moisturizing.

2. Use the application plan together

2.1 Short-distance transportation

-Recommended collocation: EPS incubator + water injection ice bag

-Use method: wrap the pre-cooled cheesecake with moisture-proof film, put it in the EPS incubator, and place the water injection ice bag evenly in the box to ensure the stable temperature. This collocation is suitable for urban distribution or short-distance transport needs.

2.2 Medium-distance and long-distance transportation

-Recommended collocation: EPP incubator + technology ice

-How to use it: wrap the cheesecake with plastic wrap, put it into the EPP incubator, and place the technology ice at the bottom and around the box to ensure a long time and low temperature environment. EPP incubator has high strength, suitable for repeated use and reduces long-term cost.

2.3 High-value products or long-distance transportation

-Recommended collocation: VIP incubator + gel ice bag

-Use method: wrap the cheesecake with moisture-proof film, put it in the VIP incubator, and place the gel ice bag evenly in the box to ensure very low temperature and lasting cooling effect. The VIP incubator has excellent heat insulation performance, suitable for high-end products and long-distance international transportation.

3. Temperature monitoring service

3.1 Real-time monitoring equipment

To ensure temperature control during transport, we placed temperature monitoring equipment in the incubator. This device can monitor the temperature change in the box in real time to ensure that the temperature is always maintained below 4°C. This not only guarantees the quality of the cheesecake, but also allows customers to know the temperature of the transportation process at any time, providing higher transparency and safety.

3.2 Temperature data record

Temperature monitoring equipment can record temperature data throughout transportation. The data can be viewed in real time through a mobile phone or computer, and customers can keep abreast of the temperature changes during transportation. If a temperature abnormality is found, immediate measures can be taken, such as adjusting the position of the ice pack or increasing the number of ice packs, to ensure the safety and freshness of the cheesecake.

3.3 Abnormal alarm function

Our temperature monitoring system also has an abnormal alarm function. If the temperature in the box exceeds the set range, the system will immediately issue an alarm and notify the customer and logistics personnel to handle it in time. This allows quick measures to avoid the impact of abnormal temperature on the quality of the cheesecake.

4. Customize the solutions

4.1 Personalized service

Huizhou industry knows that each customer’s needs are unique, so we provide customized temperature control solutions. Whether it is the material and size of the incubator, or the quantity and type of refrigerant, we can adjust according to the specific needs of customers. Our professional team will design the most appropriate packaging scheme according to the characteristics of cheesecake to ensure that the product is transported in the best condition.

4.2 Professional and technical support

Our team has rich experience in cold chain transportation and professional technology, and can provide customers with a full range of technical support. From the purchase of products to the design of the transportation scheme, we can provide professional advice and guidance, to ensure that every link is safe. No matter what problems customers encounter in the process of transportation, we can provide timely solutions to ensure the smooth transportation.

5. Temperature monitoring service

If you want to obtain the temperature information of your product during transportation in real time, Huizhou will provide you with a professional temperature monitoring service, but this will bring the corresponding cost.

6. Our commitment to sustainable development

1. Environmental-friendly materials

Our company is committed to sustainability and use environmentally friendly materials in packaging solutions:

-Recyclable insulation containers: Our EPS and EPP containers are made of recyclable materials to reduce environmental impact.

-Biodegradable refrigerant and thermal medium: We provide biodegradable gel ice bags and phase change materials, safe and environmentally friendly, to reduce waste.

2. Reusable solutions

We promote the use of reusable packaging solutions to reduce waste and reduce costs:

-Reusable insulation containers: Our EPP and VIP containers are designed for multiple use, providing long-term cost savings and environmental benefits.

-Reusable refrigerant: Our gel ice packs and phase change materials can be used multiple times, reducing the need for disposable materials.

3. Sustainable practice

We adhere to sustainable practices in our operations:

-Energy efficiency: We implement energy efficiency practices during manufacturing processes to reduce the carbon footprint.

-Reduce waste: We strive to minimize waste through efficient production processes and recycling programs.

-Green Initiative: We are actively involved in green initiatives and support environmental protection efforts.

7. Packaging scheme for you to choose

Post time: Jul-11-2024