Cold chain packaging solutions are designed to maintain the temperature of perishable goods (such as fresh and frozen foods, pharmaceuticals, and other temperature-sensitive products) during transportation and storage. Below are key points regarding cold chain packaging solutions:

1. Types of Cold Chain Packaging

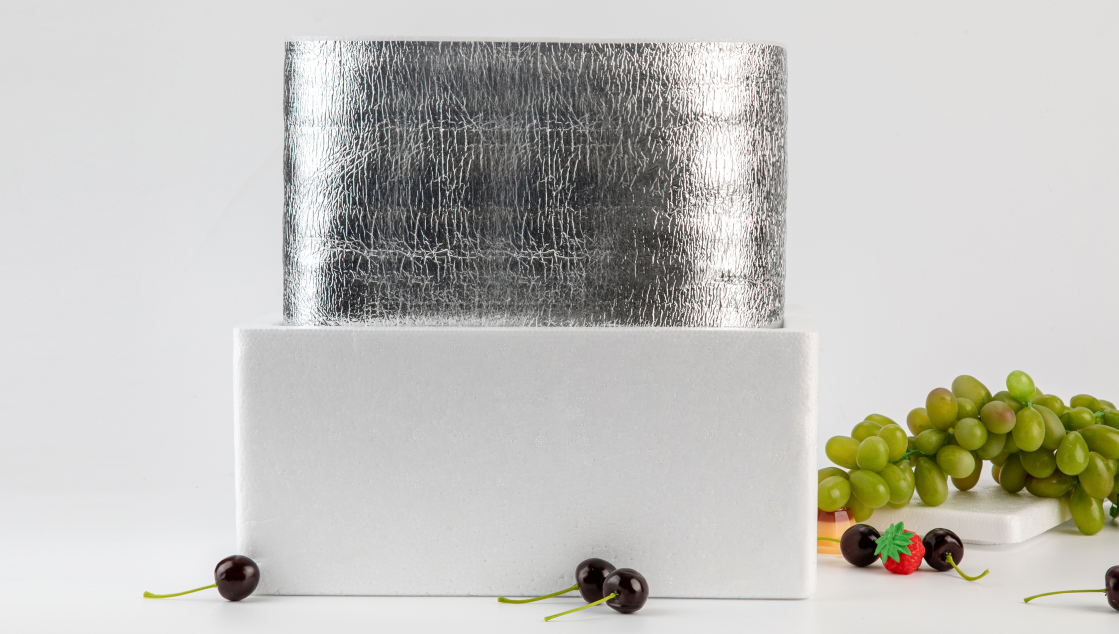

Insulated Containers: Insulated containers are specially designed to minimize heat transfer between the interior and the external environment, ensuring stable internal temperatures. They are widely used in cold chain packaging solutions for transporting and storing temperature-sensitive goods. Here are some key aspects of insulated containers:

- Working Principle:

- Insulating Materials: Made from materials with low thermal conductivity (such as foam or vacuum insulation panels) to block heat transfer.

- Multi-Layer Structure: Utilizes a multi-layer design with insulating material in between to increase thermal resistance.

- Sealed Design: Prevents external air from entering, maintaining stable internal temperatures.

- Reflective Insulation Film: Reflects thermal radiation to further reduce heat transfer.

- Types of Insulated Containers:

- Foam Boxes: Single-use insulated boxes made from foam, commonly used for short-distance cold chain transport.

- Vacuum Insulated Panel (VIP) Boxes: Reusable boxes made with vacuum insulation panels, offering superior insulation.

- Cooler Boxes/Refrigerated Boxes: Active insulated boxes equipped with cooling units, capable of maintaining low temperatures for extended periods.

The insulation performance of these containers largely depends on the thermal conductivity of the insulating material, structural design, and sealing performance. Combined with cold sources (such as dry ice or gel packs), insulated containers can provide effective cold chain protection for temperature-sensitive goods.

Cold Source Materials: Cold source materials are essential components in cold chain logistics, used to maintain a low-temperature environment during transportation and storage. Here are some common cold source materials and their features:

- Gel Packs: Made from high-polymer materials, offering strong cooling effects, reusable, and environmentally friendly.

- Dry Ice: Solid carbon dioxide with a temperature of -78.5°C, sublimates directly into gas without residue, ideal for ultra-low temperature transport.

- Phase Change Materials (PCM): Absorb or release large amounts of heat at specific temperature ranges, maintaining constant temperatures, perfect for precise temperature control in cold chain transport.

- Dry Ice Pellets: A form of dry ice in pellet form, easy to use and fast cooling, suitable for short-distance transport.

- Ice Bricks: Solid cold sources that provide excellent cooling for long periods, suitable for large-scale product transportation.

2. Phase Change Materials (PCM)

Phase change materials (PCMs) are used to maintain constant temperatures by absorbing or releasing large amounts of heat at specific temperature ranges. These materials are widely used in cold chain transport for products that require precise temperature control, such as pharmaceuticals, foods, and chemicals.

- Categories:

- Organic PCMs: Include paraffin and fatty acids, known for good latent heat and chemical stability, suitable for mid-to-low temperature ranges (-30°C to +150°C).

- Inorganic PCMs: Include salt hydrates, known for high latent heat and thermal conductivity, ideal for industrial energy storage and temperature control packaging.

- Composite PCMs: Combine organic and inorganic materials for enhanced performance, suitable for cold chain transport and energy-efficient building management.

- Working Principle: PCMs regulate temperature by transitioning between solid and liquid states, absorbing heat when the temperature exceeds the phase change point and releasing heat when the temperature drops below it.

- Advantages:

- Constant Temperature: Maintains a stable temperature within a specific range, protecting temperature-sensitive products.

- High Energy Density: Stores large amounts of energy in a small volume.

- Reusability: Can be used multiple times, making them environmentally friendly and cost-effective.

- Applications:

- Pharmaceutical Cold Chain: Used for transporting vaccines, blood products, and medications, ensuring stable low temperatures.

- Food Cold Chain: Used for transporting fresh produce, dairy products, and ice cream, maintaining freshness and quality.

3. Temperature-Controlled Packaging Liners

Temperature-controlled packaging liners are essential components in cold chain logistics, designed to maintain stable temperatures inside packaging, protecting goods from external temperature fluctuations during transport. Here are some common types of temperature-controlled packaging liners:

- Foam Liners (EPS/EPP): Lightweight, good insulation, impact-resistant, suitable for pharmaceuticals and food products.

- VIP Liners: Made from a core material and vacuum protective film, offering excellent insulation, ideal for high-value pharmaceuticals and vaccines.

- PU Foam Liners: Good insulation, durable, widely used in food and pharmaceutical transport.

- Aluminum Foil Liners: Strong reflective properties, moisture-resistant, ideal for electronic products and fresh foods.

- Silicone Liners: Soft, good high and low-temperature resistance, suitable for high-end electronics and precision instruments.

4. Temperature Monitoring Equipment

Temperature monitoring devices are used to track temperature changes during transportation, such as:

- Temperature Loggers

- Temperature Data Recorders

Different types of cold chain packaging can be combined based on transport distance, temperature requirements, and other factors to meet various cold chain transport needs.

5. Active vs. Passive Systems

Cold chain packaging solutions can be divided into active and passive systems, each with its unique features and application scenarios:

Active Systems:

- Features:

- Temperature Control: Equipped with batteries or external power sources for continuous temperature control.

- Long-Term Cooling: Suitable for long-distance transport, maintaining stable temperatures in extreme environments.

- High Efficiency: Ideal for transporting high-value and temperature-sensitive products.

- Complex Structure: Includes temperature sensors, controllers, and cooling units.

- Applications:

- Pharmaceutical Transport: Used for long-distance transport of vaccines, blood products, and high-value medications.

- Biological Samples: For transporting biological samples, requiring precise temperature control.

- High-End Foods: For international transport of high-end foods like seafood, meats, and dairy products.

- Examples:

Passive Systems:

- Features:

- No Power Requirement: Uses insulating materials and cold sources (such as gel packs, dry ice, PCMs) to maintain low temperatures.

- Lower Cost: More economical, suitable for short- to mid-distance transport.

- Simplicity: Easy to use and maintain.

- Limited Cooling Duration: The cooling duration is shorter, and more susceptible to external temperature changes.

- Applications:

- Short-Distance Transport: Suitable for transporting food, fresh produce, and pharmaceuticals.

- Delivery Services: For cold chain deliveries by e-commerce and food delivery services.

- Emergency Transport: For short-term cooling in emergencies.

- Examples:

These insights on cold chain packaging solutions offer a comprehensive understanding of how to maintain temperature stability during the transportation and storage of perishable goods.

Post time: Aug-21-2024